We design and automate data that create meaning for additive manufacturing for a higher efficiency in the 3D printing process. We emphasize on cost saving potentials when comparing to conventionally produced parts. This is by taking an holistic approach of the part’s or assembly’s entire life cycle in design, production, assembly, sourcing, warehousing and recycling.

Design

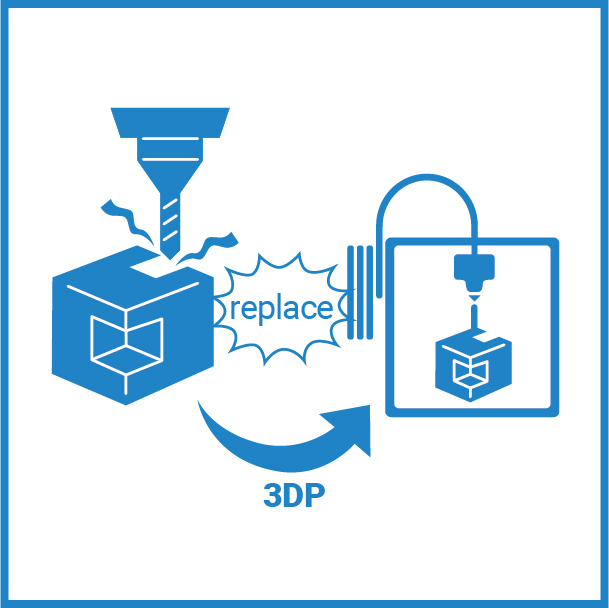

Advantages of 3D printing

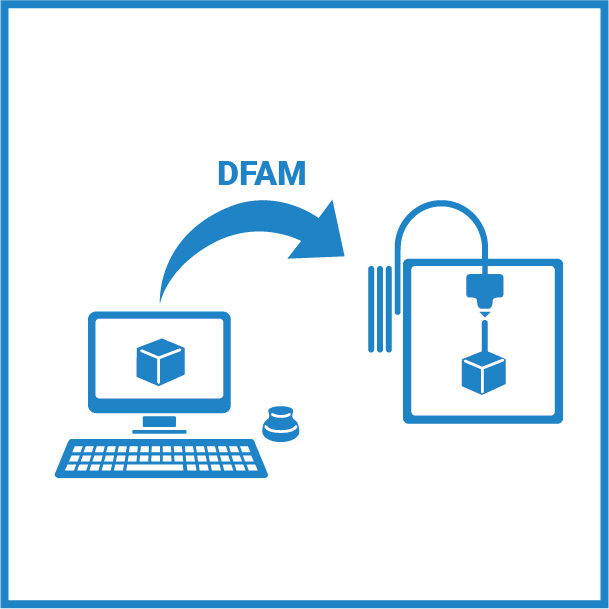

By (re-)designing for additive manufacturing (DfAM) with a production volume of over 100 part per year the customer gained a competitive edge with assembly consolidation and functional integration with the aim to avoid further assembly and calibration costs with each machine-installation. Furthermore, the costs of inventory and in maintenance were reduced by switching to a digital warehouse with on-demand delivery.

Read what a customer says:

„Phanos has helped us 3D scanning a medical sensor device for training purposes of which we only had a physical part. The master patterns were made by Phanos using a printing technique allowing for very smooth surfaces, ideally suited for serial replication with vacuum casting. This was also managed by Phanos. Each copy was individualized with a serial number.

Time management, reliability and documentation were first class and the parts are still in use as of today for over 3 years now.”

Claudia Hooijmans, CEO of MIFO